-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hi everyone, my husband has turned up on a job with a very old mains that he will need to shut down at some stage. Does anyone know the procedure for shutting down/re starting this type of mains? Photos attached. Apologies if this is the wrong forum and thanks for reading!View attachment 101397View attachment 101398

There is not enough information there.

It's clearly an ACB, and it looks like an old EE E3, which could be 3.3kV.

If he doesn't know how to operate any item of switchgear, he should be nowhere near it.

EE used the same or similar facia for most of their range, only really adding more information/options as they got higher in voltage, by the time you get to the E7 & E8 they do look significantly different to the lower voltage stuff.

This could be a 415V or 3.3kV ACB.

Edit.

If it is 415V it could be the M-pact range, likely in a form 4 switchboard, but there is no way to be sure from these photos.

Last edited:

There is not enough information there.

It's clearly an ACB, and it looks like an old EE E3, which could be 3.3kV.

If he doesn't know how to operate any item of switchgear, he should be nowhere near it.

EE used the same or similar facia for most of their range, only really adding more information/options as they got higher in voltage, by the time you get to the E7 & E8 they do look significantly different to the lower voltage stuff.

This could be a 415V or 3.3kV ACB.

Edit.

If it is 415V it could be the M-pact range, likely in a form 4 switchboard, but there is no way to be sure from these photos.

Thanks for your help, unfortunately there is no other information available.There is not enough information there.

It's clearly an ACB, and it looks like an old EE E3, which could be 3.3kV.

If he doesn't know how to operate any item of switchgear, he should be nowhere near it.

EE used the same or similar facia for most of their range, only really adding more information/options as they got higher in voltage, by the time you get to the E7 & E8 they do look significantly different to the lower voltage stuff.

This could be a 415V or 3.3kV ACB.

Edit.

If it is 415V it could be the M-pact range, likely in a form 4 switchboard, but there is no way to be sure from these photos.

He would not work on an item that he does not know how to operate, hence my asking for information - we're trying to find someone that has worked on these to assist - we've drawn a blank so far but hopefully your additional information may help, so thanks again.

Thanks for your help, unfortunately there is no other information available.

He would not work on an item that he does not know how to operate, hence my asking for information - we're trying to find someone that has worked on these to assist - we've drawn a blank so far but hopefully your additional information may help, so thanks again.

It is pretty important you get the right information, English Electric made the OB3 in the 1950s - this MUST NOT BE OPERATED!

It was redesigned to be the M-pact in the 60s and EE got swallowed up by GEC in the late 60s, after this the M-pact became the GEC M-pact (now known as the mk 1) since then it's become the mk2, new M-pact, M-pact plus etc.

The ob3 and M-pact mk1 look similar when you just have the small view as your photo.

Hello Katie.Hi everyone, my husband has turned up on a job with a very old mains that he will need to shut down at some stage. Does anyone know the procedure for shutting down/re starting this type of mains? Photos attached. Apologies if this is the wrong forum and thanks for reading!View attachment 101397View attachment 101398

Tell your husband not to touch it. There is almost certainly high energy present (arc flash hazard); it should have been risk-assessed and labelled as such. If so, that means arc-rated PPE is essential to safely operate this circuit breaker. The lack of arc flash labelling and circuit designation labels leads me to think it has not been maintained. If the site owner does not know how to operate it, it may not have been functioned for an unknown period of time and may be unsafe. Call the DNO; they have all the right PPE to deal with it and will also be able to service and test it, which will be required. It then needs to go on a routine maintenance schedule and be risk-assessed for the potential arc flash hazard. And, usually, the lower the service voltage, the greater the arc flash hazard, so don't relax if it's found to be "only" 415 volts. Keep well away from it in the interim.

Regards,

Colin Jenkins.

Thank you, he is going to contact the DNO, thanks for all your advice.It is pretty important you get the right information, English Electric made the OB3 in the 1950s - this MUST NOT BE OPERATED!

It was redesigned to be the M-pact in the 60s and EE got swallowed up by GEC in the late 60s, after this the M-pact became the GEC M-pact (now known as the mk 1) since then it's become the mk2, new M-pact, M-pact plus etc.

The ob3 and M-pact mk1 look similar when you just have the small view as your photo.

Thanks, he is contacting the DNO, really appreciate your help.I've used some later descendants - GE M-Pact motor wound spring (MWS) units. The post above says it all, don't do it!

Thanks so much, he is contacting the DNO as suggested. Really appreciate the help.Hello Katie.

Tell your husband not to touch it. There is almost certainly high energy present (arc flash hazard); it should have been risk-assessed and labelled as such. If so, that means arc-rated PPE is essential to safely operate this circuit breaker. The lack of arc flash labelling and circuit designation labels leads me to think it has not been maintained. If the site owner does not know how to operate it, it may not have been functioned for an unknown period of time and may be unsafe. Call the DNO; they have all the right PPE to deal with it and will also be able to service and test it, which will be required. It then needs to go on a routine maintenance schedule and be risk-assessed for the potential arc flash hazard. And, usually, the lower the service voltage, the greater the arc flash hazard, so don't relax if it's found to be "only" 415 volts. Keep well away from it in the interim.

Regards,

Colin Jenkins.

A wise move. Thanks for reassuring us.

A key point here is that an ACB of this type, is not something that you just operate without forethought. Even if you are skilled and familiar with the equipment, the procedure used needs to take account of the local conditions, maintenance status or lack of it, load being interrupted, prospect of closing onto a fault etc, all of which would be built into the risk assessment for the activity.

These things can be deceptive. They sit quietly for decades giving an impression of solid reliability, but without actually being called upon to perform their job and without the maintenance necessary to keep them ready to spring into action. Then, when someone finally presses the button and the neglected mechanism malfunctions, it erupts into a fireball.

A key point here is that an ACB of this type, is not something that you just operate without forethought. Even if you are skilled and familiar with the equipment, the procedure used needs to take account of the local conditions, maintenance status or lack of it, load being interrupted, prospect of closing onto a fault etc, all of which would be built into the risk assessment for the activity.

These things can be deceptive. They sit quietly for decades giving an impression of solid reliability, but without actually being called upon to perform their job and without the maintenance necessary to keep them ready to spring into action. Then, when someone finally presses the button and the neglected mechanism malfunctions, it erupts into a fireball.

Corrected that for you.Then, when someone finally presses the button and the neglected mechanism malfunctions, it erupts into a massive viral hit on Youtube.

A wise move. Thanks for reassuring us.

A key point here is that an ACB of this type, is not something that you just operate without forethought. Even if you are skilled and familiar with the equipment, the procedure used needs to take account of the local conditions, maintenance status or lack of it, load being interrupted, prospect of closing onto a fault etc, all of which would be built into the risk assessment for the activity.

These things can be deceptive. They sit quietly for decades giving an impression of solid reliability, but without actually being called upon to perform their job and without the maintenance necessary to keep them ready to spring into action. Then, when someone finally presses the button and the neglected mechanism malfunctions, it erupts into a fireball.

If it is an OB3 it would be dependent manual operation.

Which means it closes as slowly as you operate it!

People have been known to start opening them, halfway through closing them because they hear arcing.

It does indeed turn into a fireball.

M-pact and the E series could be independent manual, manual charged spring, motor charged spring, or solenoid.

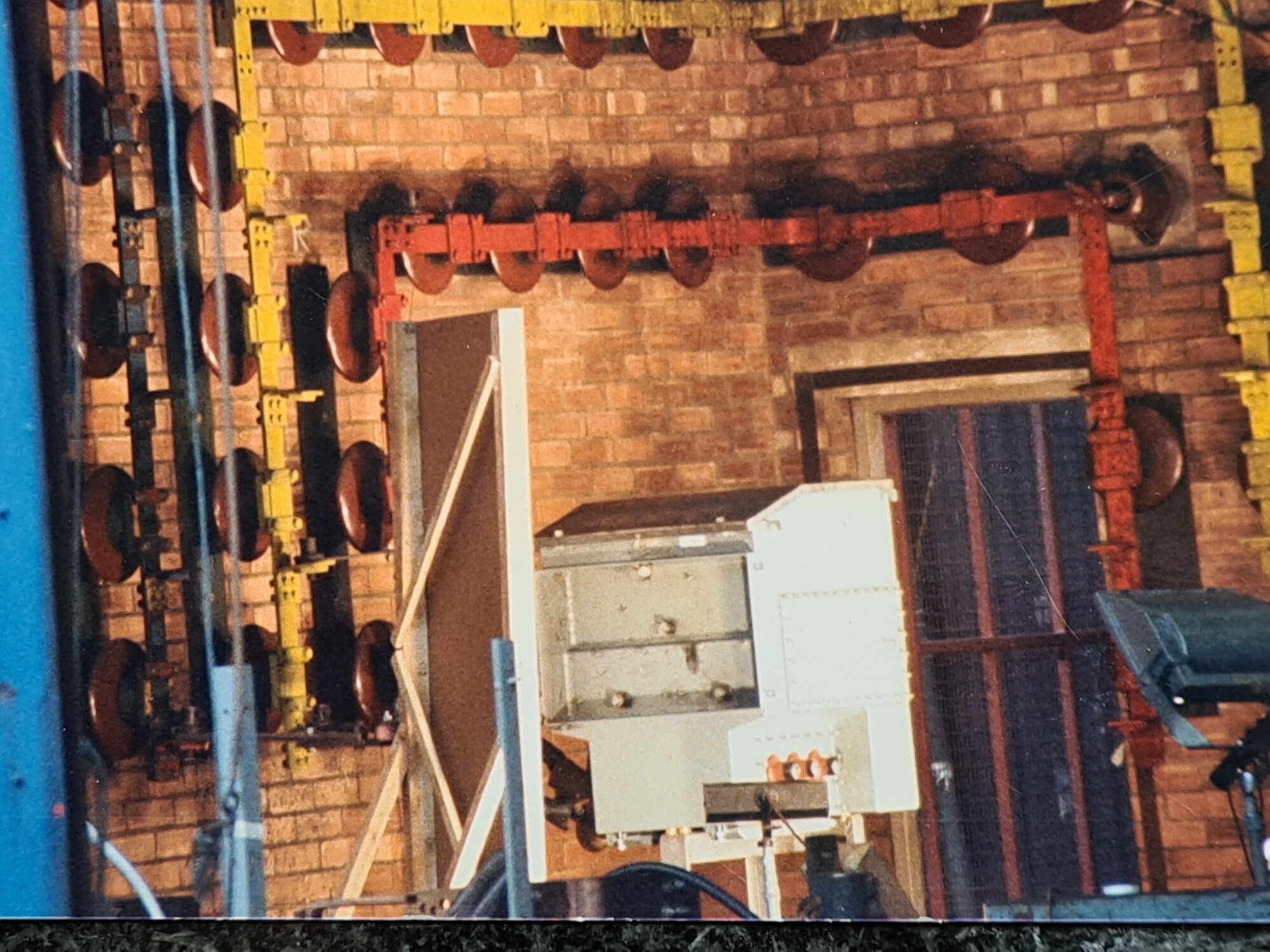

To give a small example, this is a test where I applied a small fault to a piece of switchgear with a minor manufacturing fault (deliberate), the piece of heat sensitive board to the front-left of the switchgear is the size and in the place where the operator would be when operating it.

Unfortunately although you can see the "operator" pushed back, the angle obscures the view - the material was burnt right through in places, indicating the operator could have suffered 3rd/4th degree burns to 75/40% of their body.

Unfortunately although you can see the "operator" pushed back, the angle obscures the view - the material was burnt right through in places, indicating the operator could have suffered 3rd/4th degree burns to 75/40% of their body.

Last edited:

Vortigern

Arms

What are those disc things all around the room. In fact, what is that room? @Julie. And, errr, I have made a solemn promise to myself to not operate an air circuit breaker anytime soon!

P.S. And why must the OB3 NOT BE OPERATED? Is/was it defective like the above? All very interesting by the way.

P.S. And why must the OB3 NOT BE OPERATED? Is/was it defective like the above? All very interesting by the way.

Last edited:

What are those disc things all around the room. In fact, what is that room? @Julie. And, errr, I have made a solemn promise to myself to not operate an air circuit breaker anytime soon!

Look like insulators with bus bars mounted on them I think? Looks very interesting eh!

To give a small example, this is a test where I applied a small fault to a piece of switchgear with a minor manufacturing fault (deliberate), the piece of heat sensitive board to the front-left of the switchgear is the size and in the place where the operator would be when operating it.

View attachment 101428

View attachment 101429

View attachment 101430

View attachment 101431

View attachment 101432

View attachment 101433

Unfortunately although you can see the "operator" pushed back, the angle obscures the view - the material was burnt right through in places, indicating the operator could have suffered 3rd/4th degree burns to 75/40% of their body.

You've broken that.

I think it is the "dependant operation" aspect, in other words unless you can and know how to make the damn thing operate VERY QUICKLY you get a serious arc-flash/arc-blast risk.P.S. And why must the OB3 NOT BE OPERATED? Is/was it defective like the above? All very interesting by the way.

I'm not even sure if that is allowed any more?

A quick search finds this useful document:

I has the requirements on page4 of:

I has the requirements on page4 of:

- prohibiting the operation of dependent manually-operated switchgear when live, except under very carefully controlled conditions;

- when possible, replacing the closing mechanism for dependent manually-operated switchgear. When this is not possible, you must replace the switchgear;

People have been known to start opening them, halfway through closing them because they hear arcing.

To use a flight analogy, it's like trying to abort a takeoff after V1, which you only do if the aircraft is incapable of flight. It is better to continue, even if you suspect there is a problem, than to create a worse one by aborting. In an aircraft that would be a runway excursion, with switchgear it's the aforementioned fireball.

Operating open front switchgear on 250-500V DC at lower currents, you can get a clear idea of how an arc behaves according to what you do with the switch handle, without the risk of the severe arc-flash injury that comes with failed MV or HV or even high current LV switching events. IMO every electrical apprentice should get to see and feel this.

What are those disc things all around the room. In fact, what is that room? @Julie. And, errr, I have made a solemn promise to myself to not operate an air circuit breaker anytime soon!

P.S. And why must the OB3 NOT BE OPERATED? Is/was it defective like the above? All very interesting by the way.

The red Yellow and blue busbars are the three phases we connected the equipment to, we could choose the voltage on those from 200V to 38kV depending upon the test requirements, the disks are insulators.

That is a test bay at a switchgear testing station, low - medium voltage, unfortunately I don't have photos of the other bays some of which go to high voltage (66kV+)

The OB3 operates like many of the era and is known as "dependant manual"

This means the speed of contact closure is completely dependent upon the operator, if you are hesitant and do it slowly or even stop and reverse, then the contacts will not make properly.

Switchgear is generally designed to close onto a fault, but opening a fault is not always required (switches), and when it is able to interrupt a fault (breaker), they sometimes use different contacts, and in any case they always need to follow the proper cycle from: contact made, contact separation, arc, arc control, then arc extinction then fully open.

Dependant manual interrupts this cycle.

As long as you make a swift closure, even on to a fault, the breaking cycle can complete safely.

As you may guess I worked at both a switchgear manufacturer and testing station , unfortunately I had to go out and investigate some incidents including a number where deaths had been involved.

I did attend one where an operator had started to close a switch (~11kV) designed in the late '40s manufactured in the 50s - so dependant manual, and realised he hadn't removed the earth links, so hesitated half way through and tried to open it.

5 out of the 6 people in the switchroom died, the one who lived was near the door managed to get out but was engulfed in the burning oil, it was horrific to be honest, one of the worst I investigated.

The red Yellow and blue busbars are the three phases we connected the equipment to, we could choose the voltage on those from 200V to 38kV depending upon the test requirements, the disks are insulators.

That is a test bay at a switchgear testing station, low - medium voltage, unfortunately I don't have photos of the other bays some of which go to high voltage (66kV+)

The OB3 operates like many of the era and is known as "dependant manual"

This means the speed of contact closure is completely dependent upon the operator, if you are hesitant and do it slowly or even stop and reverse, then the contacts will not make properly.

Switchgear is generally designed to close onto a fault, but opening a fault is not always required (switches), and when it is able to interrupt a fault (breaker), they sometimes use different contacts, and in any case they always need to follow the proper cycle from: contact made, contact separation, arc, arc control, then arc extinction then fully open.

Dependant manual interrupts this cycle.

As long as you make a swift closure, even on to a fault, the breaking cycle can complete safely.

As you may guess I worked at both a switchgear manufacturer and testing station , unfortunately I had to go out and investigate some incidents including a number where deaths had been involved.

I did attend one where an operator had started to close a switch (~11kV) designed in the late '40s manufactured in the 50s - so dependant manual, and realised he hadn't removed the earth links, so hesitated half way through and tried to open it.

5 out of the 6 people in the switchroom died, the one who lived was near the door managed to get out but was engulfed in the burning oil, it was horrific to be honest, one of the worst I investigated.

That's really scary that.

A YouTube search for “breaker failure” shows a tragic case of someone presumably winding out a switch under load. (Upsetting video - they don’t survive the massive explosion)

There are a few nasty ones on YouTube.

Wow @Julie. never realised what sort or work you did. Way past my pay grade and sounds absolutely fascinating. Plus your worked maths on 3P obviously way up there. Good for you. Nice to see a woman in such a place.

Long career!

First job was at a motor rewind company, they said I would need to do a few office duties, but would go down the engineering route, it was a lie. I was just a receptionist

I managed to start as an apprentice for a switchgear company, they partnered with a couple of utilities and a large electrical installation company. After doing the rounds of all departments internally and external, from inspection through the foundry and site stuff like lv installation, and the rounds of a couple of utilities like their apprentices; I went to University, and moved into the testing arena, then the design department - I ended up being quite senior.

I presented quite a few papers on some specialist research, as at one time I was split between working at the factories in Stafford, and Manchester; the Electrical Research Association in Chester, and doing a further degree at UMIST all associated with modelling electrical field theory and its effects - one area was the use of protective suits whilst operating switchgear - it isn't just flameproof, they have electrical characteristics as well.

Just a few lines for so many years!

After that I moved to a college as a lecturer, which I hated, so moved on rather quickly to a protection company, (everything from lv through transmission line stuff, big on distance protection, motor and generation) then a few consulting companies mainly doing fault level, and protection analysis and design and so on.

Having got a bit sick of the technical side (very challenging, but little money or respect) I moved into tech project management - an absolute doddle, but lots of money. I managed installations of turbine generators/CHP schemes around the world.

Sick of working away, back to consulting, but increasingly away from high voltage to installation type stuff over the last 20 years or so.

So a bit of a wide range of stuff!

Been back and forward between consulting, doing, and managing, over the years - it's somewhat more intertwined than the above summary suggests.

Should have retired several years ago, at 55 then savings and personal pensions until 60, then with personal and state pension, but the b#$%@#&$ shifted it to 67 before I get state pension. So just kind of semi-retired waiting for a good point to retire fully.

I think its safe to say that @Julie. Knows a bit about this electricity stuff.

During my career in the engineering and manufacturing industry's

I can only think of 4 Engineers that I consider really good in their field of work (proper engineers, not technicians that call themselves engineers)

3 of them are women, this is an unusual statistic because of how few women work in the engineering field compared to men.

Its hard to say without appearing patronising or sexist but well done to all the women who excel in the field of engineering because there have been and probably still are many obstacles they had to climb to get where they are today, that a man in the same position may not have encountered.

During my career in the engineering and manufacturing industry's

I can only think of 4 Engineers that I consider really good in their field of work (proper engineers, not technicians that call themselves engineers)

3 of them are women, this is an unusual statistic because of how few women work in the engineering field compared to men.

Its hard to say without appearing patronising or sexist but well done to all the women who excel in the field of engineering because there have been and probably still are many obstacles they had to climb to get where they are today, that a man in the same position may not have encountered.

I think its safe to say that @Julie. Knows a bit about this electricity stuff.

During my career in the engineering and manufacturing industry's

I can only think of 4 Engineers that I consider really good in their field of work (proper engineers, not technicians that call themselves engineers)

3 of them are women, this is an unusual statistic because of how few women work in the engineering field compared to men.

Its hard to say without appearing patronising or sexist but well done to all the women who excel in the field of engineering because there have been and probably still are many obstacles they had to climb to get where they are today, that a man in the same position may not have encountered.

As the saying goes, "For a woman to be considered half as good as a man, she has to be twice as good"

Fortunately, such a challenge is easily achieved

Just kidding, but it's kind of an open goal!

Yes, full respect deserved there!I think its safe to say that @Julie. Knows a bit about this electricity stuff.

I used to teach electronics many years back, and it was always disappointing to see how few women applied to study the degree in the first place as it represents a huge loss of potential talent that has gone elsewhere. That issue is a wider one for school and society to fix, alas.During my career in the engineering and manufacturing industry's

I can only think of 4 Engineers that I consider really good in their field of work (proper engineers, not technicians that call themselves engineers)

3 of them are women, this is an unusual statistic because of how few women work in the engineering field compared to men.

Its hard to say without appearing patronising or sexist but well done to all the women who excel in the field of engineering because there have been and probably still are many obstacles they had to climb to get where they are today, that a man in the same position may not have encountered.

In 2016 when we (myself and two others from a now-closed facility) to India for a meeting with ISRO we were pleasantly surprised to find that almost half of the 12 predominantly engineering/software folks at the meeting were women. I even made a point of writing to the top guy we had been dealing with to praise their achievement.

You made me laugh out loud then!!As the saying goes, "For a woman to be considered half as good as a man, she has to be twice as good"

Fortunately, such a challenge is easily achieved

Just kidding, but it's kind of an open goal!

I take it back, maybe you should have stayed as the receptionist, polished your nails, ignored the telephone, and worked part time as a comedian!!

Actually that might have paid me more!I take it back, maybe you should have stayed as the receptionist, polished your nails, ignored the telephone, and worked part time as a comedian!!

Vortigern

Arms

Ouch..As the saying goes, "For a woman to be considered half as good as a man, she has to be twice as good"

Fortunately, such a challenge is easily achieved

Just kidding, but it's kind of an open goal!

Actually that might have paid me more!

Anyway @Julie. if you are ever stuck for a bit of cash I could probably use you for a bit of house-bashing when the pension days hit. Clearly you know a bit about electrics. In truth a captivating story. It is surprising the stories there are no doubt on here. Who knew?

I would guess we all have interesting stories, I would further guess a number of them couldn't be shared on a public forum!!!

Similar threads

- Replies

- 3

- Views

- 543

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread starter

- Joined

- Location

- Cirencester

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United Kingdom

- What type of forum member are you?

- Electrical Engineer (Qualified)

Thread Information

- Title

- English Electric Mains shut down/start up procedure

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 36

- Unsolved

- --

Advert

Advert

TrueNAS JBOD Storage Server

-

-

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8