_q12x_

DIY

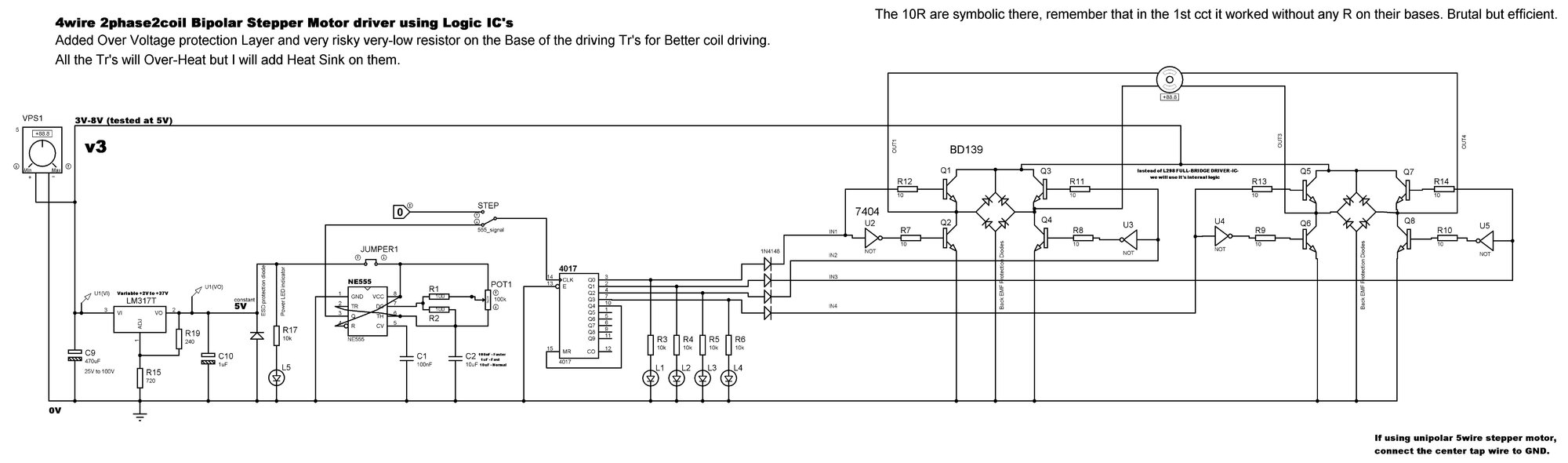

Actually there is another forum discussion until reaching this cct here. It was an entire evolution of it.

This cct is working ok but in certain parameters. It is limited to power and heat over the Tr's.

Is working fine in the 5V range for 2 of my stepper motors that I tested with it. But if Im bringing up the voltage, to 10V, I get 140dgrC on one Tr and about 60dgrC on a few others. At 5V, everything stays at a constant 50dgrC which I call it normal and safe.

One of the test motor is a Nema17 17HS4401. The other one is a scrapped stepper. Both work fine at 5V and even at 10V, no one was heating. Over 5V, especially at 10V, only the driver's Tr's were cooked to (almost)death. I stopped the power after smelling hot metal in the air.

I am also receiving a couple of L298N IC's. They are coming in the mail, not arrived yet. But I dont expect much difference from them, compared to what I have here. It would be nice to be better ! I hope so.

- My question:

- How to make this cct more powerful? To drive more power through the coils of the stepper motor? (and not blow up it's Tr's!)

I already have 2 answers to this question in my mind, but I dont want to influence your answer. I expect to be pleasantly surprised. Haha.

Thank you !

Thank you !

This cct is working ok but in certain parameters. It is limited to power and heat over the Tr's.

Is working fine in the 5V range for 2 of my stepper motors that I tested with it. But if Im bringing up the voltage, to 10V, I get 140dgrC on one Tr and about 60dgrC on a few others. At 5V, everything stays at a constant 50dgrC which I call it normal and safe.

One of the test motor is a Nema17 17HS4401. The other one is a scrapped stepper. Both work fine at 5V and even at 10V, no one was heating. Over 5V, especially at 10V, only the driver's Tr's were cooked to (almost)death. I stopped the power after smelling hot metal in the air.

I am also receiving a couple of L298N IC's. They are coming in the mail, not arrived yet. But I dont expect much difference from them, compared to what I have here. It would be nice to be better ! I hope so.

- My question:

- How to make this cct more powerful? To drive more power through the coils of the stepper motor? (and not blow up it's Tr's!)

I already have 2 answers to this question in my mind, but I dont want to influence your answer. I expect to be pleasantly surprised. Haha.