Dartlec

Arms

Called to look at a job today for a previous client. Tumble Drier giving off 'funny smell' and tripped the RCD - Called out her appliance insurance plan people, who suggested it was the fixed wiring - hence why she wanted me to have a look...

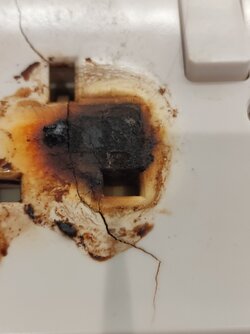

Plug and socket well and truly melted...

Clearly due to over heating or loose connection of some sort from first glance.

However, removing the socket, wiring and terminals behind showing no damage at all: Nor is there any sign of loose connection when retracting the shielding on the live pins...

It's a GET socket, so not the usual cheap and nasty ones where I've seen melting before. All the damage appears to be on the front.

And the cable feeding the socket still flexible with no sign of heat damage. (This is a single circuit 16A MCB)

The plug has a fairly obvious bulge on the top (not quite so clear in the pictures)

as well as the obvious damage around the fuse carrier/live pin...

So my view is that the problem was in the moulded plug on the appliance which then caused the socket damage, either due to prolonged over heating, or some fault within it - or the drier is now running above it's rated 2800W and over time has caused the plug to over heat and melt....

The drier is a relatively old AEG, which has been repaired a few times before...

The appliance people wanted to just put a new socket and plug on, but I'm of the view that they should be checking a bit further to see what the fault is before declaring it safe.

Client would like them to write it off and get a new one since she's worried (rightly) about fire risk. I'm going to put a site report together stating that the fixed wiring was not at fault and that the issue was clearly with the appliance and that it should be tested and declared safe by an approved appliance engineer before being reused...

I PAT tested the appliance, and it passed, at least under the new code, with a 0.93 mA leakage but IR fine and earth loop still intact...

Anyone like to add their experience or wisdom?

Cable to the appliance still seemed fine with no heat damage. If I was reconnecting this myself, I'd be tempted to run it from an appliance outlet plate since it's on a 16A MCB, but the drier does state requirements for 13A fuse (although in this case it doesn't appear to have gone)

Drier was under a worktop if that matters - Circuit is a single radial from 16A MCB to an outlet plate, where 1.5mm flex feeds the single socket shown...

Plug and socket well and truly melted...

Clearly due to over heating or loose connection of some sort from first glance.

However, removing the socket, wiring and terminals behind showing no damage at all: Nor is there any sign of loose connection when retracting the shielding on the live pins...

It's a GET socket, so not the usual cheap and nasty ones where I've seen melting before. All the damage appears to be on the front.

And the cable feeding the socket still flexible with no sign of heat damage. (This is a single circuit 16A MCB)

The plug has a fairly obvious bulge on the top (not quite so clear in the pictures)

as well as the obvious damage around the fuse carrier/live pin...

So my view is that the problem was in the moulded plug on the appliance which then caused the socket damage, either due to prolonged over heating, or some fault within it - or the drier is now running above it's rated 2800W and over time has caused the plug to over heat and melt....

The drier is a relatively old AEG, which has been repaired a few times before...

The appliance people wanted to just put a new socket and plug on, but I'm of the view that they should be checking a bit further to see what the fault is before declaring it safe.

Client would like them to write it off and get a new one since she's worried (rightly) about fire risk. I'm going to put a site report together stating that the fixed wiring was not at fault and that the issue was clearly with the appliance and that it should be tested and declared safe by an approved appliance engineer before being reused...

I PAT tested the appliance, and it passed, at least under the new code, with a 0.93 mA leakage but IR fine and earth loop still intact...

Anyone like to add their experience or wisdom?

Cable to the appliance still seemed fine with no heat damage. If I was reconnecting this myself, I'd be tempted to run it from an appliance outlet plate since it's on a 16A MCB, but the drier does state requirements for 13A fuse (although in this case it doesn't appear to have gone)

Drier was under a worktop if that matters - Circuit is a single radial from 16A MCB to an outlet plate, where 1.5mm flex feeds the single socket shown...