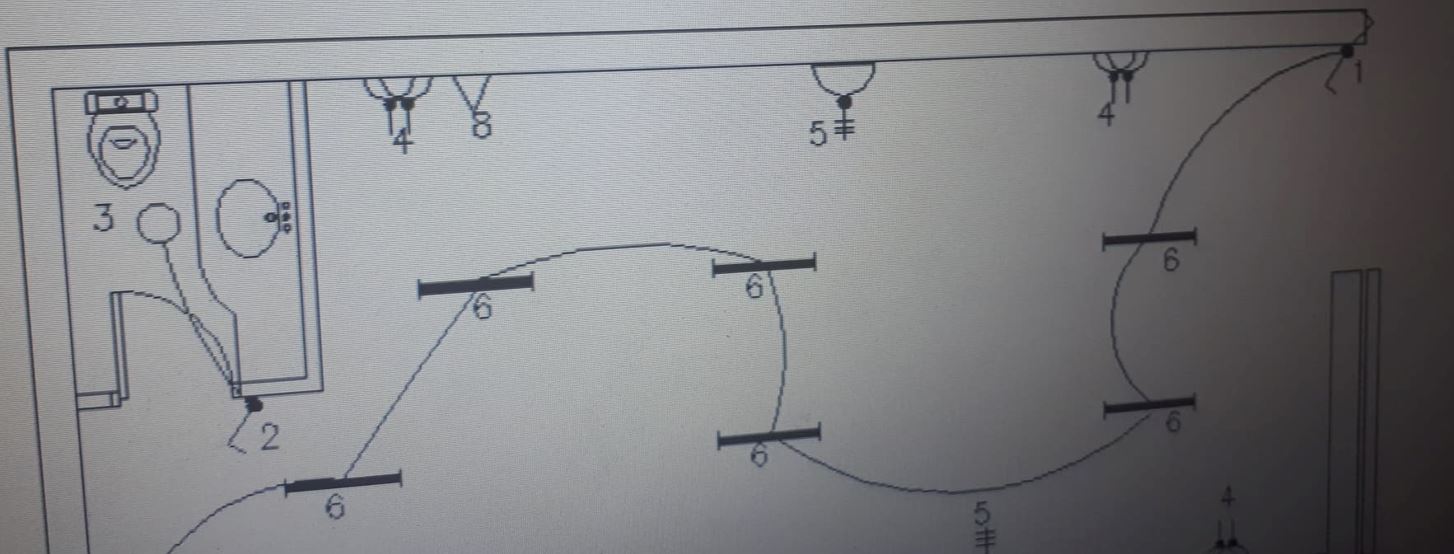

I have been given this assignment "the drawing below shows the floor plan of a small factory with the electrical symbols. Explain the process of designing the final electrical circuit that supplies all the elements 6 . The total length of the circuit is 25m. Any assumptions you have to make should be indicated" and I have no idea how to do it. If anyone could help I would be greatful

-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I am new to the field and I am still studying electrician. I dont know what to do and how to proceed.Start with known factors and work from there.

You know the total length of the circuit and what it is serving.

N

nicebutdim

I'm a first year apprentice, but this is fairly straightforward. I haven't provided an answer for two reasons:

1. I'm not familiar with regulations in Cyrprus.

2. Doing so wouldn't assist with your learning, so I'm trying to point you in the right direction.

Ask yourself what additional factors are involved in the design of this simple circuit? Are you povided with details of luminaire or is this something you have to decide on? You need to specify cable size and type of breaker - both of which can be determined from available information.

1. I'm not familiar with regulations in Cyrprus.

2. Doing so wouldn't assist with your learning, so I'm trying to point you in the right direction.

Ask yourself what additional factors are involved in the design of this simple circuit? Are you povided with details of luminaire or is this something you have to decide on? You need to specify cable size and type of breaker - both of which can be determined from available information.

We are learning from the BS7671I'm a first year apprentice, but this is fairly straightforward. I haven't provided an answer for two reasons:

1. I'm not familiar with regulations in Cyrprus.

2. Doing so wouldn't assist with your learning, so I'm trying to point you in the right direction.

Ask yourself what additional factors are involved in the design of this simple circuit? Are you povided with details of luminaire or is this something you have to decide on? You need to specify cable size and type of breaker - both of which can be determined from available information.

I have to write about the overload calculations, voltage drop, shock protection and thermal constrains?

For us, yes!Is this part of an apprenticeship, study for basic electrical qualification or design course?

Can you please provide me with the answer?

N

nicebutdim

You've answered part of it by listing cosiderations which must be taken into account.

You know circuit length and number of points served. Do you know power consumption of luminaires? Have you been given information about containment ,or is this something you would have to determine? I ask as this impact upon thermal constraints.

Overcurrent protection will be determined from total load, cable type, inrush current etc.

So far you have made no attempt at answering the question and have simply provided some basic information in the hope that it will be answered for you. I'll attempt to help, and am certain others will step in, if you want help, but no one is going to provide all the answers as that won't help you to learn.

You know circuit length and number of points served. Do you know power consumption of luminaires? Have you been given information about containment ,or is this something you would have to determine? I ask as this impact upon thermal constraints.

Overcurrent protection will be determined from total load, cable type, inrush current etc.

So far you have made no attempt at answering the question and have simply provided some basic information in the hope that it will be answered for you. I'll attempt to help, and am certain others will step in, if you want help, but no one is going to provide all the answers as that won't help you to learn.

It looks like it's just for the lighting?

You might need to assess the current., and all the other things that @nicebutdim helpfully mentioned.

Can't give you the answer, as there will be many approaches here.

Put down your assumptions, then spec the design to those.

If you get bits wrong, you will have learned something useful.

You might need to assess the current., and all the other things that @nicebutdim helpfully mentioned.

Can't give you the answer, as there will be many approaches here.

Put down your assumptions, then spec the design to those.

If you get bits wrong, you will have learned something useful.

No.Can you please provide me with the answer?

You need to provide with your answer and folks on here will try and help you improve it until it is acceptably good. Otherwise you have not demonstrated any learning!

Start with the spec of the lights, work out the total power (or more correctly, current) is needed. Assuming it's LED then it'll be fairly low.

You can now have a stab at picking a cable size - though in practice the answer will almost certainly be "the minimum allowed by the regs" (it's in there, you find it ).

).

You can then work out volt drop and check that it's within limits (again, it's in the book) - if not, then you'd have to up the cable size, find another way of improving things, or decide whether the excess is an acceptable deviation from the standard.

Pick an upstream overcurrent protection type and rating, work out if it's compatible with the fault impedance. Consider the characteristics of the loads when selecting the OCP - for example, if you had a big space with loads of flouro tubes, there's scope for significant inrush current. Most types of light have some sort of inrush - some more than others.

You'll also have to consider the CCC of the cable taking into account the installation method.

If necessary, you may need to iterate. E.g., if you have a larger than typical Ze or Zs, or a long circuit length, you might find that the overall fault impedance isn't acceptable for the OCP you've chosen. So then you need to consider what options there are to fix that.

So there's the steps you should already know - off you go, find the information, and do the calcs. Voila, circuit designed.

You can now have a stab at picking a cable size - though in practice the answer will almost certainly be "the minimum allowed by the regs" (it's in there, you find it

You can then work out volt drop and check that it's within limits (again, it's in the book) - if not, then you'd have to up the cable size, find another way of improving things, or decide whether the excess is an acceptable deviation from the standard.

Pick an upstream overcurrent protection type and rating, work out if it's compatible with the fault impedance. Consider the characteristics of the loads when selecting the OCP - for example, if you had a big space with loads of flouro tubes, there's scope for significant inrush current. Most types of light have some sort of inrush - some more than others.

You'll also have to consider the CCC of the cable taking into account the installation method.

If necessary, you may need to iterate. E.g., if you have a larger than typical Ze or Zs, or a long circuit length, you might find that the overall fault impedance isn't acceptable for the OCP you've chosen. So then you need to consider what options there are to fix that.

So there's the steps you should already know - off you go, find the information, and do the calcs. Voila, circuit designed.

-

Thread 'JBOD Suppliers; JBOD Storage Server Suppliers. Who is best out of the 5 options?'

Just found some info. Here are five well-known and...- Dan

- Replies: 4

-

Thread 'Electrical sub station near heathrow airport 'blows up'? - possible russians?'

Wondering if this Heathrow thing it outside state actors...- Dan

- Replies: 23

-

Thread 'Fake JIB Cards and City & Guilds Qualifications'

Today we have been contacted by another company based in...- RWJ

- Replies: 37

-

-

Thread 'Day from hell!!'

Had an absolute howler of a day, been beating myself up...- Welsh_sparky_21

- Replies: 14

-

Join in the Eurovision Song Contest 2015 Thread

Please come join in the Eurovision Song Contest 2025...- Dan

- Replies: 11

-

Thread 'Forum Sponsor News Area'

https://www.electriciansforums.net/forums/forum-sponsor-n...- Dan

- Replies: 0

Similar threads

- Replies

- 3

- Views

- 385

Best EV Chargers by Electrical2Go! The official electric vehicle charger supplier.

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread starter

- Joined

- Location

- cyprus

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- All Other Countries (This Is English Speaking Website Only - WE don't mind Google Translate Users :)

- What type of forum member are you?

- Other

- If other, please explain

- student

Thread Information

- Title

- Explain the process of Designing a Final circuit

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 11

- Unsolved

- --

Advert

Advert

TrueNAS JBOD Storage Server

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8

-