Master Mech

DIY

I have just had some work carried our to rewire a lighting circuit in my house due to it having no earthing.

The lighting circuit is the original lighting circuit that was installed when the house was built in the 50's which was ran in steel conduit.

We now want to fit metal accessories but obviously require earthing for this to be safe so a rewire of this circuit is required & to be honest has been way overdue for replacement anyway.

Like most people I did not fancy chasing all the walls out to install new cables so asked the electrician if the steel conduit already plastered into the walls could be used saving the need to chase the walls out & redecoration.

He said that would not be an issue after looking over the installation as there would be enough room for the new cabling to be fed down the old conduit which was great news.

When he came to install the new cabling here found that he could not install the twin & earth cabling with the sheath attached as there was not enough room inside the conduit.

His solution was to strip the sheath from the twin & earth cabling and then wrap all the individual wires together in electrical insulation tape.

Removing the sheath created the room required to be able to feed the cables down the existing conduit.

Where the conduit ends in the loft space he left the sheath on the cables & the ran them to a junction box.

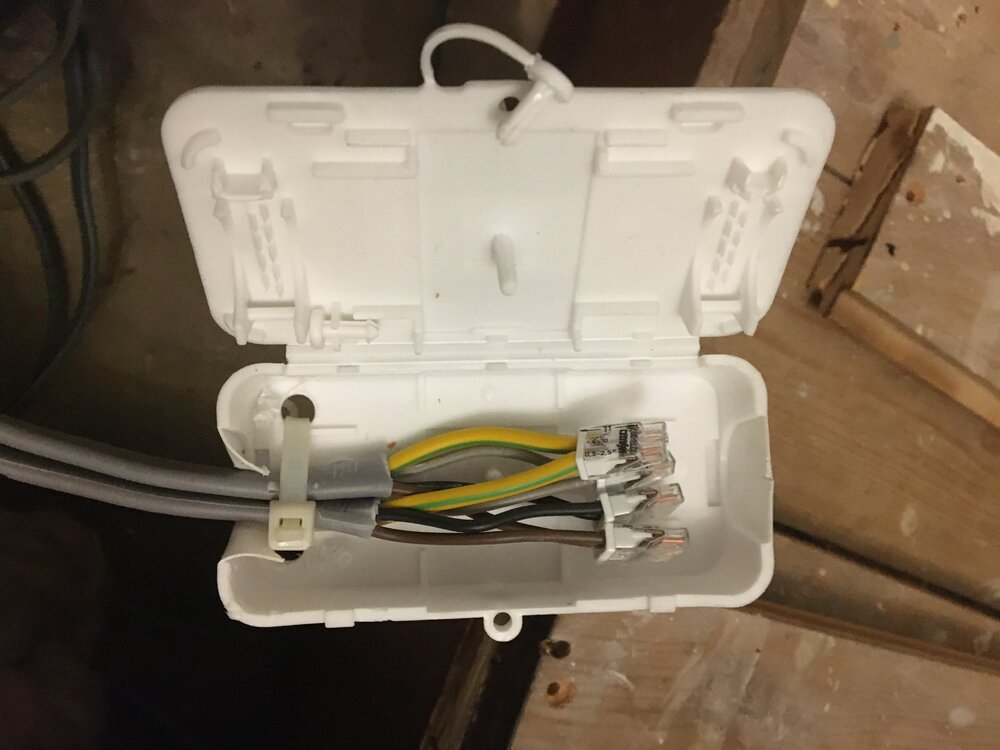

Here are some pictures of the junction box in the loft space & the tops of where the conduit for the switch drops end.

The same lighting circuit also covers not only the upstairs bedrooms but the landing, hallway & dining room lighting so cables needed to be ran under the landing floor boards & junction boxes installed.

Here are some pictures of the junction boxes under the landing floorboards.

So my question is are there any issues with how this work has been carried out?

I am probably making a mountain out of a mole hill but I would really appreciate your input.

Many thanks

Adam

The lighting circuit is the original lighting circuit that was installed when the house was built in the 50's which was ran in steel conduit.

We now want to fit metal accessories but obviously require earthing for this to be safe so a rewire of this circuit is required & to be honest has been way overdue for replacement anyway.

Like most people I did not fancy chasing all the walls out to install new cables so asked the electrician if the steel conduit already plastered into the walls could be used saving the need to chase the walls out & redecoration.

He said that would not be an issue after looking over the installation as there would be enough room for the new cabling to be fed down the old conduit which was great news.

When he came to install the new cabling here found that he could not install the twin & earth cabling with the sheath attached as there was not enough room inside the conduit.

His solution was to strip the sheath from the twin & earth cabling and then wrap all the individual wires together in electrical insulation tape.

Removing the sheath created the room required to be able to feed the cables down the existing conduit.

Where the conduit ends in the loft space he left the sheath on the cables & the ran them to a junction box.

Here are some pictures of the junction box in the loft space & the tops of where the conduit for the switch drops end.

The same lighting circuit also covers not only the upstairs bedrooms but the landing, hallway & dining room lighting so cables needed to be ran under the landing floor boards & junction boxes installed.

Here are some pictures of the junction boxes under the landing floorboards.

So my question is are there any issues with how this work has been carried out?

I am probably making a mountain out of a mole hill but I would really appreciate your input.

Many thanks

Adam