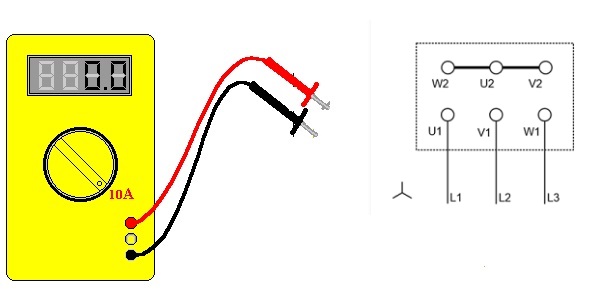

Hello everyone, friends. In cases where I do not have a clamp meter, I want to measure the current drawn by the phases of a 3-phase motor with my multimeter. I left a picture below as an example. I connected my red probe to 10A., my black probe to Com. After turning the multimeter to 10A; For example, where should I connect the red and black probes to measure the current drawn by the L1 phase?

-

Pro's OnlyElectricians Arms Electrician Talk How to Access The Arms Domestic Electrician Industrial Electricians Wiring, Theories, Regulations Engineering Chat Periodic Testing Problems Electricians Downloads Commercial Electricians Security (Access-Only) Access Private Area Business Related Advice Certification Schemes Electrical & PAT Testing

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

You would have to disconnect the L1 wire from the motor and put the meter in series with the connection to the motor.

You cannot do it by just probing terminals.

That is why a clamp meter is so useful, as you do not have to interfere with the wiring.

I hope you are not planning to actually do this! Much safer to use a clamp meter.

You cannot do it by just probing terminals.

That is why a clamp meter is so useful, as you do not have to interfere with the wiring.

I hope you are not planning to actually do this! Much safer to use a clamp meter.

I hope you are not planning to actually do this!

I'm interested to know why you say this. A clamp meter is much more convenient and can be safer, but there's nothing inherently unsafe about using a meter for its intended purpose. I sometimes break into a circuit if it's likely to have a troublesome waveform that the clamp might not accurately capture, especially with DC.

To be fair, unless i knew someone's knowledge level i would not recommend this manor of testing either.I'm interested to know why you say this. A clamp meter is much more convenient and can be safer, but there's nothing inherently unsafe about using a meter for its intended purpose. I sometimes break into a circuit if it's likely to have a troublesome waveform that the clamp might not accurately capture, especially with DC.

firstly they would have to figure out if the meter will survive the testing both during normal running and start up stage.

2nd it would normally require some additional conversion leads being made up to safely terminate the probes to the incoming live and outgoing motor terminal.

unlike measuring a voltage like the op was assuming where you just put the probes against something and take a reading, a good reliable connection must be maintained for the duration of the motor run, not just whilst you test it to take a reading.

and then 3rd you really need to repeat this test for the other 2 phases for the results to be a lot of use.

Edit, i am not suggesting the practice is inherently unsafe, just not something i would recommend to someone who i didn't know.

I have and am sure others have done things as a temporary rig up to test a theory that look a lot worse than that diagram above.

Purely concerned about the safety of the OP, who didn't appear familiar with the scenario. I've no problem with using an AvoI'm interested to know why you say this.

I will remove the L1 phase from the motor and connect it to the Black probe, then I will hold the red probe to the U1 input on the motor. Do I understand correctly?You would have to disconnect the L1 wire from the motor and put the meter in series with the connection to the motor.

You cannot do it by just probing terminals.

That is why a clamp meter is so useful, as you do not have to interfere with the wiring.

I hope you are not planning to actually do this! Much safer to use a clamp meter.

View attachment 107870

What is the full load current of the motor.

Before doing this you must first determine what the maximum start-up current for the motor should be, and that has to be less than the multimeter is rated for.I will remove the L1 phase from the motor and connect it to the Black probe, then I will hold the red probe to the U1 input on the motor. Do I understand correctly?

You must also be sure the meter is rated to at least CAT-III safety. This means it will have a fast internal fuse for the current range(s) and if the start-up current of the motor exceeds this by any significant amount it will blow the meter's fuse. If that happens then you will need to replace the fuse with another of the correct current and breaking capacity rating.

Making a mistake with an inadequately rated test meter can literally result in it exploding in your face. Not joking here, sadly folks have died that way.

The surge can be dealt with by connecting a single pole switch in the L1 supply, rather than breaking it, with the meter leads connected to each switch terminal.

Start the motor with the switch closed, and then open it.

An alternative method of measuring the run current is to fit a low value resistor in series with each supply. The resistor value and wattage should be chosen, by Ohms and Watts laws, so that there is a couple of volts or so across each resistor at the expected run current.

Measure the resistance of each resistor accurately, and then measure the voltage across each resistor with the motor running. It's then a simple matter to calculate the current in each phase.

Start the motor with the switch closed, and then open it.

An alternative method of measuring the run current is to fit a low value resistor in series with each supply. The resistor value and wattage should be chosen, by Ohms and Watts laws, so that there is a couple of volts or so across each resistor at the expected run current.

Measure the resistance of each resistor accurately, and then measure the voltage across each resistor with the motor running. It's then a simple matter to calculate the current in each phase.

Although @brianmoooore 's advice is very good and useful, I have to side with @Avo Mk8 & @James that as soon as you have to do anything fancy to safely use a multimeter, you are better to simply use a clamp ammeter.

Generally if the expected load is above an amp or so (so switch-on surge can take out 10A fuse, for example) and especially if you are trying to interrupt a live circuit or working on anything with high fault currents, then a clamp meter is the way to go.

True, the jaws can be too large for some locations, but a short length of comparable wire to give to a long enough cable to measure is about as safe & simple a change as you can make to facilitate the test.

Generally if the expected load is above an amp or so (so switch-on surge can take out 10A fuse, for example) and especially if you are trying to interrupt a live circuit or working on anything with high fault currents, then a clamp meter is the way to go.

True, the jaws can be too large for some locations, but a short length of comparable wire to give to a long enough cable to measure is about as safe & simple a change as you can make to facilitate the test.

M

Marvo

I wouldn't do this test by just holding the probes onto the terminal and wire, you need to figure out a way to make the probe connections more permanent and less prone to moving around or slipping.I will remove the L1 phase from the motor and connect it to the Black probe, then I will hold the red probe to the U1 input on the motor. Do I understand correctly?

I'd advise against doing the test this way although it's not inherently a 'bad' test there's several ways it could go pear shaped for someone that's not experienced.

Of course a clamp meter is far preferable, but my post was to illustrate that there's more than one way of killing a cat, so to speak.Although @brianmoooore 's advice is very good and useful, I have to side with @Avo Mk8 & @James that as soon as you have to do anything fancy to safely use a multimeter, you are better to simply use a clamp ammeter.

Both my methods avoid the problem of switching heavy currents with meter probes.

Don’t hold it on with your fingers or you will be the latest dodo to become extinctI will remove the L1 phase from the motor and connect it to the Black probe, then I will hold the red probe to the U1 input on the motor. Do I understand correctly?

Similar threads

- Question

- Replies

- 9

- Views

- 1K

- Question

- Replies

- 5

- Views

- 431

OFFICIAL SPONSORS

These Official Forum Sponsors May Provide Discounts to Regular Forum Members - If you would like to sponsor us then CLICK HERE and post a thread with who you are, and we'll send you some stats etc

Advert

Thread starter

- Joined

- Location

- abd

- If you're a qualified, trainee, or retired electrician - Which country is it that your work will be / is / was aimed at?

- United States of America

- What type of forum member are you?

- Practising Electrician (Qualified - Domestic or Commercial etc)

- If other, please explain

- beginner,beginner

Thread Information

- Title

- Current measure with multimeter (help)

- Prefix

- N/A

- Forum

- UK Electrical Forum

- Replies

- 12

- Unsolved

- --

Thread Tags

Advert

Advert

TrueNAS JBOD Storage Server

-

-

Understanding TrueNAS JBOD Servers: A Comprehensive Guide

- Started by Dan

- Replies: 8

-