Okay so, I have a shed down the end of my garden where I like to weld and do stupid stuff. Anyway I have an arc welder which at maximum power gives me 160A @ 20V which is 3200W. When my parents built the shed they didn't take into account that there son was going to be a raging metal melting maniac and hence there is just 2 G-pin 13A @ 230V AC sockets in the entire shed, very inconsiderate I know. This of course allows for a maximum of 2990W which just isn't good enough if I want to weld thick steel without the fuse going every 2 seconds.

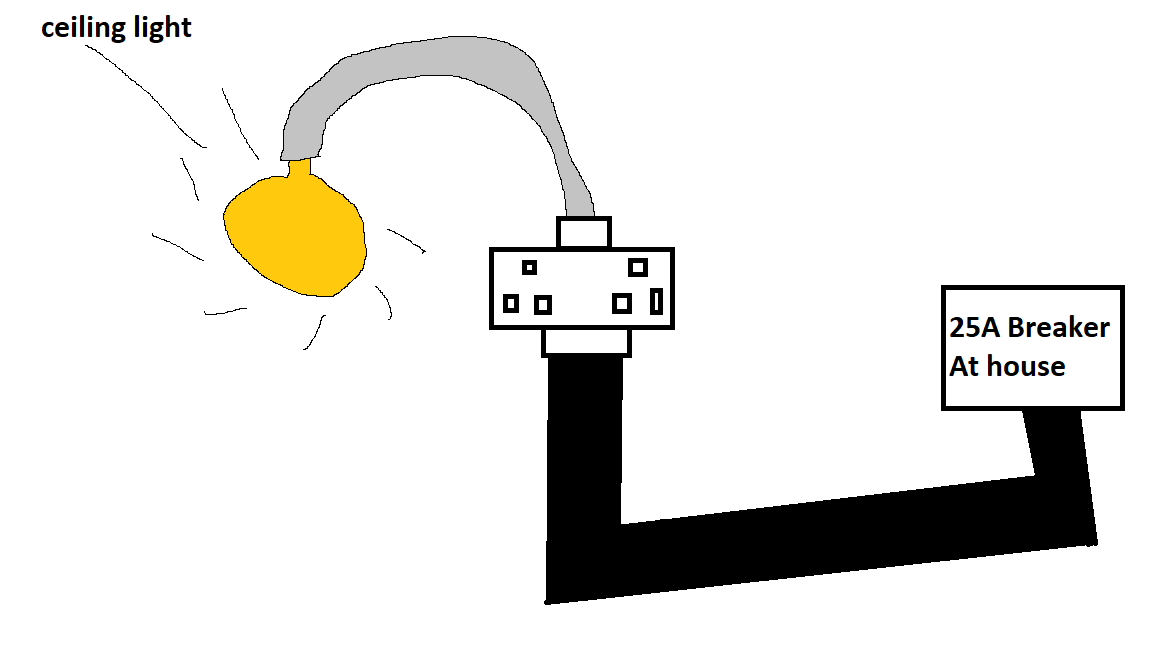

Luckily the electrician clearly saw my future struggles and popped in a 25A breaker for the shed on the mains board back up at the house when it was built. But here's where things get a little iffy: The cable for the shed comes in though a big dirty black wire from the house underground and goes straight into the G-pin sockets and then a smaller grey wire goes from the sockets to the strip light up above. (I've attached a highly detailed diagram below) I assumed that the strip light was just in parallel with the power coming into the sockets and turning off the power for the shed at the breaker would therefore turn off the sockets and the lights. But alas it only turned off the sockets and the lights are still fully functional. I don't know what witchcraftery this is but I don't really want to open up the socket and have a peak if there's live electricity going through her. My plan was to just attach a big 16Amp connector to the big dirty cable but it seems a bit tricky as I've no idea whats going on inside the socket.

Thanks in advance,

Peter

Luckily the electrician clearly saw my future struggles and popped in a 25A breaker for the shed on the mains board back up at the house when it was built. But here's where things get a little iffy: The cable for the shed comes in though a big dirty black wire from the house underground and goes straight into the G-pin sockets and then a smaller grey wire goes from the sockets to the strip light up above. (I've attached a highly detailed diagram below) I assumed that the strip light was just in parallel with the power coming into the sockets and turning off the power for the shed at the breaker would therefore turn off the sockets and the lights. But alas it only turned off the sockets and the lights are still fully functional. I don't know what witchcraftery this is but I don't really want to open up the socket and have a peak if there's live electricity going through her. My plan was to just attach a big 16Amp connector to the big dirty cable but it seems a bit tricky as I've no idea whats going on inside the socket.

Thanks in advance,

Peter