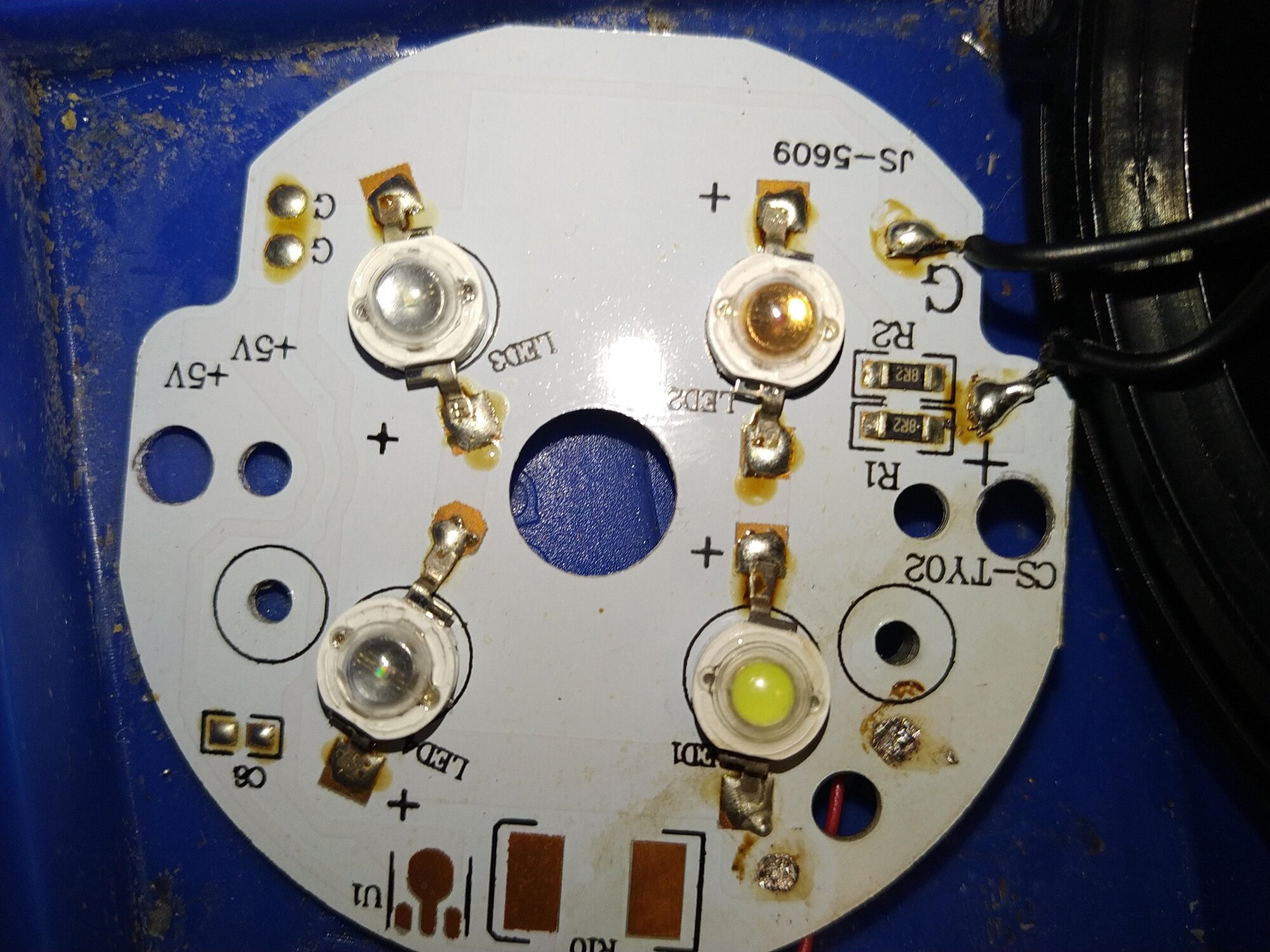

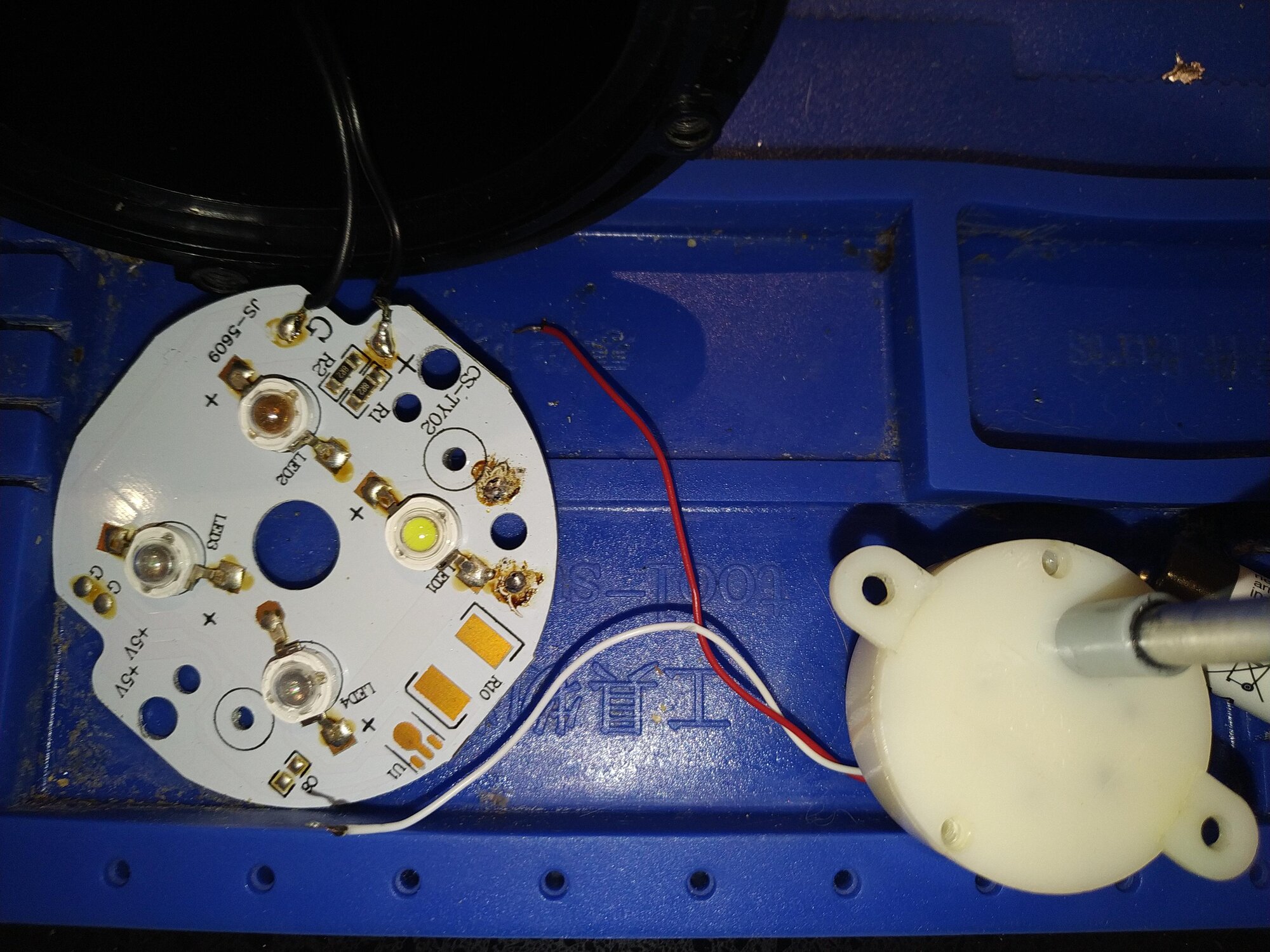

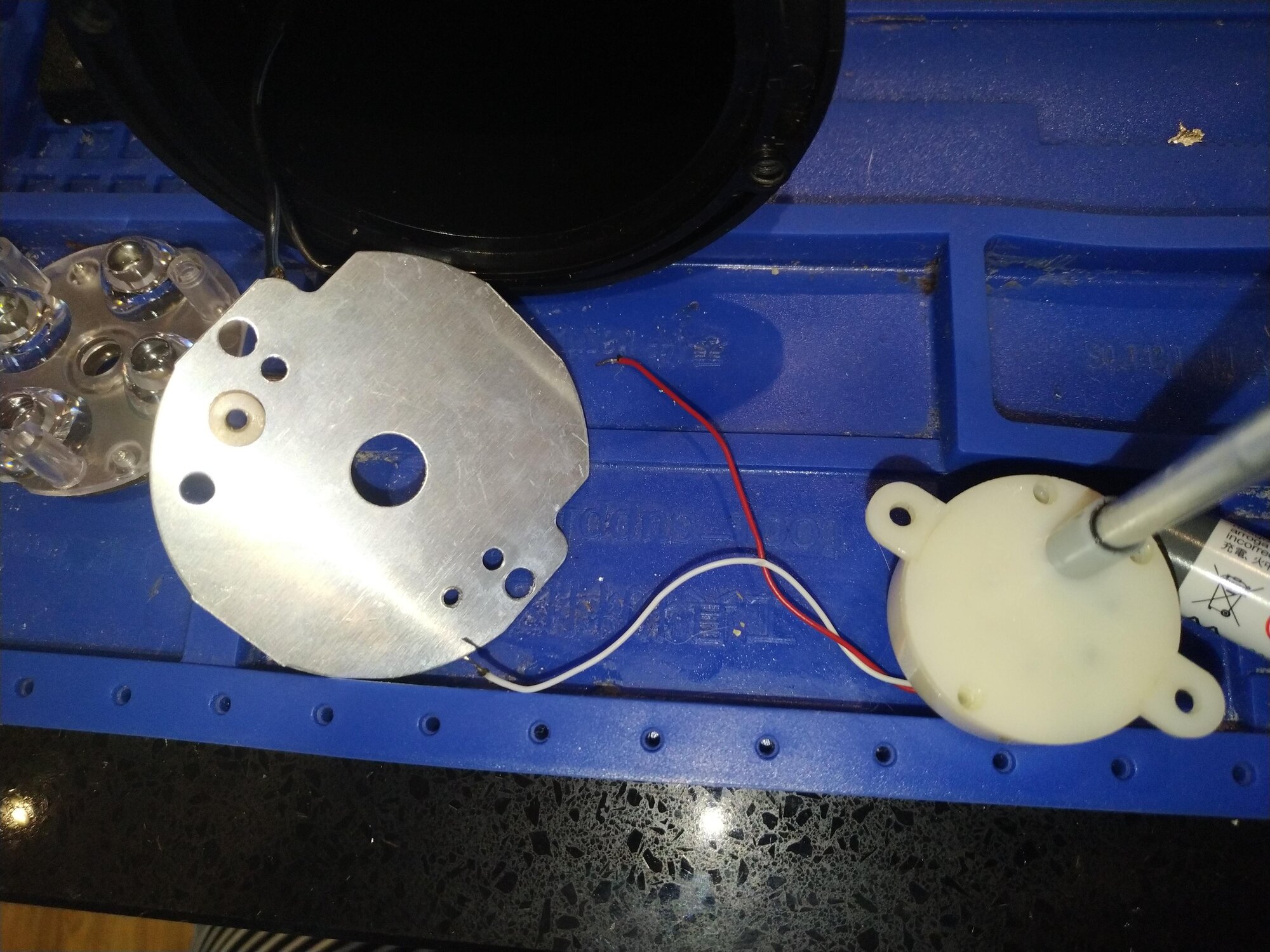

I disassembled a Christmas light projector to try and identify the cause of why the images from the projector weren't moving at all, when they used to. Looks like a couple of wires have come loose between the board and the motor wires.

I'm not sure which points they need to be soldered back on to. If I try the two empty contacts on the board, there isn't any movement in the motor. Other combinations cause one more more of the LEDs to lose power, so not sure what to do/what I am missing.

Could someone please help?

Many thanks.

I'm not sure which points they need to be soldered back on to. If I try the two empty contacts on the board, there isn't any movement in the motor. Other combinations cause one more more of the LEDs to lose power, so not sure what to do/what I am missing.

Could someone please help?

Many thanks.

![bQwbwH3[1].jpg](https://electricians.s3.eu-west-1.amazonaws.com/data/attachments/76/76440-68b59e7f1cab11eb5fbb2ed9d034ddd8.jpg?hash=aLWefxyrEe)